Introduction & Application

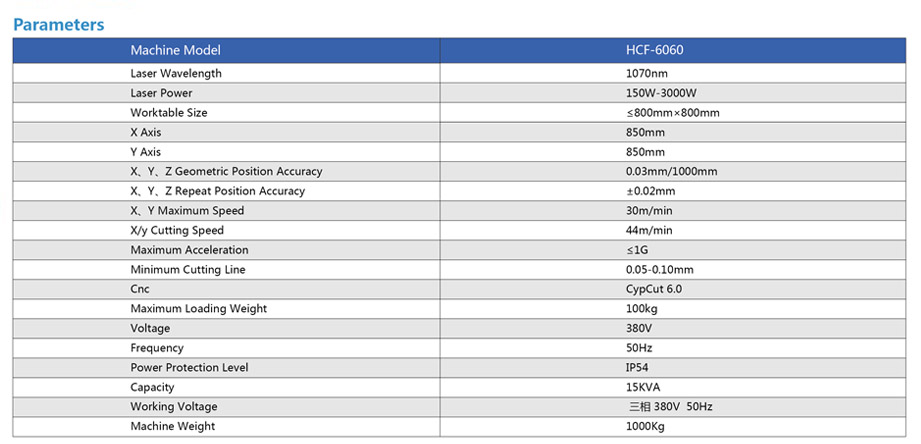

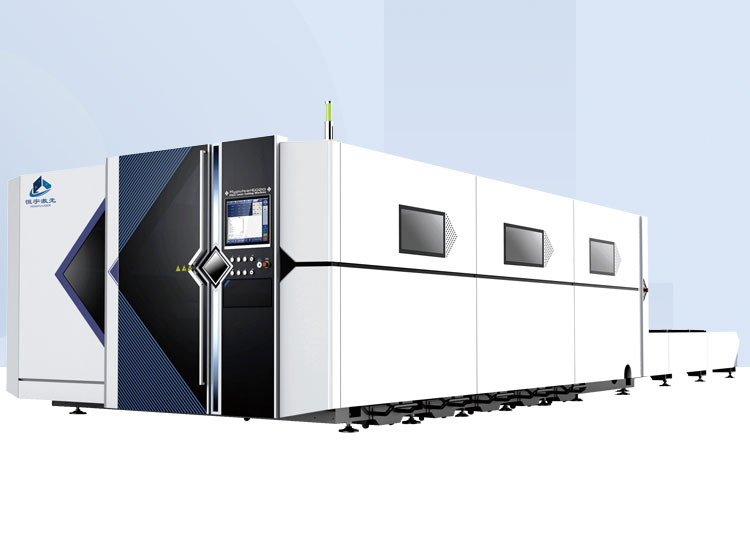

HCF high precision laser cutting machine series adopts high precision grinding lead screw, imported high precision linear guide

and other efficient transmission mechanism, imported servo motor. The precision CNC optical fiber laser cutting machine is a high

-tech product integrating laser cutting,precision machinery and numerical control technology. It is mainly used for cutting and forming

metal materials such as carbon steel plate, stainless steel plate, aluminium alloy and titanium alloy. It has the characteristics of high

speed, high precision, high efficiency and high cost performance. It is the preferred cutting machine in metal material processing industry.

Applicable Materials (150W-3000W Laser source): Specialized in cutting a variety of medium-thin metal plates, high-quality cutting

of 0.5-20mm carbon steel plate, 0.5-10mm stainless steel plate, 0.5-10mm aluminum alloy plate, 0.5-8mm brass, but also cutting galv

-anized plate, electrolytic plate, silicon steel, titanium alloy, aluminum-galvanized plate and other metal materials.

Equipment advantage

High precision: high precision grinding lead screw and high precision linear guide, imported servo drive configuration, stable transmis-

sion, high precision.

Good rigidity and stability: the whole body adopts work piece fixed, gantry mobile structure, the machine bed adopts integral welding

structure, vibration treatment, eliminate the welding and processing stress completely, good rigidity, high accuracy, no distortion and

other advantages.

Small dimension: Machine tool embodies the design concept of highly integrated, its structure is compact, beautiful, generous, using

fixed worktable structure,suitable worktable operation height provides a comfortable operating environment.

Easy to operate: Professional PC industrial computer and PMC control card, easy to operate; Professional cutting control software

supports automatic editing of CAD graphics and text. Two-axis and three-axis controlled CNC laser cutting machine, in which X-axis

and Y-axis are combined to realize planar cutting feed and Z-axis is floating to track the work piece surface.

Cutting thickness: Cutting 0.5-20 mm carbon steel plate, 0.5-10mm stainless steel plate, and cutting aluminum plate and other metal plates.

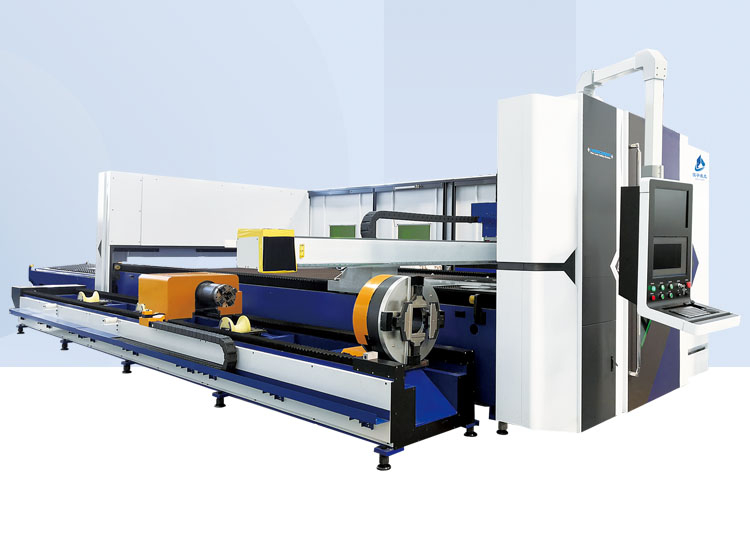

HyTube Series Ⅰ Automatic Prof…

Technology Advantage? Using the bus numerical control system based on Windows operating s…

HyPulsar Cheetah Series Laser C…

Introduction & Application HyPulsar cheetah series laser cutting system integration …

HySonics Eagle Series Laser Cut…

Introduction & Application HySonics series is high-speed and high-power fiber laser c…

HySonics-R Series Tube & S…

Technology Advantage◆ Independently develops the integrated machine of sheet and tube. It…

3D-metal laser cutting machine

Introduction & Application The three-dimensional fiber laser cutting robot is an adv…